|

|

Electromagnetic chuck suitable for both grinding and EDM operations. |

|

|

Fine division permanent chuck suitable for both grinding and EDM operations. |

|

|

Universal low-profile workholding chuck that offers maximum effective holding on the widest range of workpiece shapes and sizes. |

|

|

Permanent magnetic micro pitch design chucks that are ideal for reliable clamping of very thin and small components for precision grinding. It holds large workpieces as well. |

|

|

Transverse bar pole chucks specially designed for smaller, thinner workpieces and tool steel. |

|

|

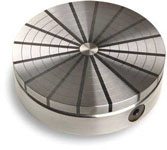

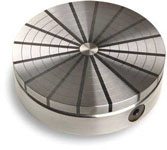

Permanent rotary magnetic chucks that have a radial pole design with neodymium (rare earth) magnet for holding rings and bearing races, as well as solid rounds. |

|

|

|

|

|

Rotary electromagnetic and electro-permanent chucks are made in radial pole multi-coil design for use in hard turning and free state grinding. The radial pole design is recommended for holding circular workpieces such as rings and discs. |

|

|

Electro-permanent magnetic workholding chucks designed for light to heavy milling applications. |

|

|

Permanent magnetic chucks are designed using neodymium magnets for milling applications. |

|

SMART-B SERIES |

Automatic release chuck control. Full, variable and residual holding. Designed to be used with electromagnetic chucks. |

|

SMART-C SERIES |

Automatic release chuck control. Full, variable and residual holding. Designed to be used with electromagnetic chucks |

|

SMART-D SERIES |

Automatic release chuck control. Full, variable and residual holding. Designed to be used with electromagnetic chucks |

|

SCV SERIES |

Manual release chuck control designed to be used with electromagnetic chucks. |