Walker understands the importance of getting your magnet back up and running in optimal condition in order to minimize downtime. We offer exceptional repair services for all our magnets and even repair other magnet brands as well.

General Magnet Service and Repair

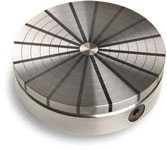

Walker repairs ALL makes of magnetic chucks as well as Walker lifting magnets and Walker magnetic separators.

Even if your magnetic chucks, separators, and lifting magnets are currently working as expected, engaging Walker Magnetics for regular maintenance services is highly recommended. When you contact us for industrial magnet service, we will inspect your unit and controls for any worn-out parts, corroded connections, broken cam-links or other potential problems.

This will allow us to make any needed adjustments now, so that your chuck or magnet does not break down while in service, shutting down your operation and possibly necessitating an expensive repair. Regular maintenance is also the best way to extend the life of your magnets for as long as possible.

In addition, if your lift magnets are not working at the optimal functioning level in which you received them, due to age and wear, we can recondition your magnets, restoring their performance for a fraction of what it would cost you to buy an entirely new magnet.

Lifting Magnet Repair

As you might expect, the experts in lifting magnet manufacturing also offer superior industrial magnet repair.

We begin by doing a complete mechanical and electrical evaluation and opening a Magnet Service Report. This is followed by disassembling the magnet and inspecting the component parts to see which parts need replacement or reconditioning. We then generate a repair quote. Once you approve that quote, we will clean and sandblast the parts of your magnet and clean and inspect the conductor.

Next, we create a CAD drawing and bill of materials, followed by winding the coils with Nomex insulation and tying off the coils with vertical copper straps. Unlike other repair companies, we use Alculpate to join the aluminum conductor to the last two turns of the copper conductor to prevent galvanic corrosion.

We then inspect the components against OEM drawings, remanufacture to the latest revision, machine and prepare to reassemble. Reassembly includes installing the coil in the case, insulating, inserting the bottom plate, pressing it to 4,000 PSI and tack welding, and finally semi-automatically welding the magnet with a stainless-steel weld for a permanent watertight seal.

Finally, we vacuum-impregnate the magnet with an insulating potting compound and bake it. Once reassembly is complete, we electrically test the magnet, paint it, make sure all the chains and pins are attached, and ship it back to you. You will not find a more comprehensive process for industrial magnet repair.

Return Materials Authorization

Request an RMA Number. Any item that is shipped to Walker Magnetics from a customer must be accompanied by an RMA.

Spare Parts

Walker offers spare parts for various do-it-yourself magnet repairs.